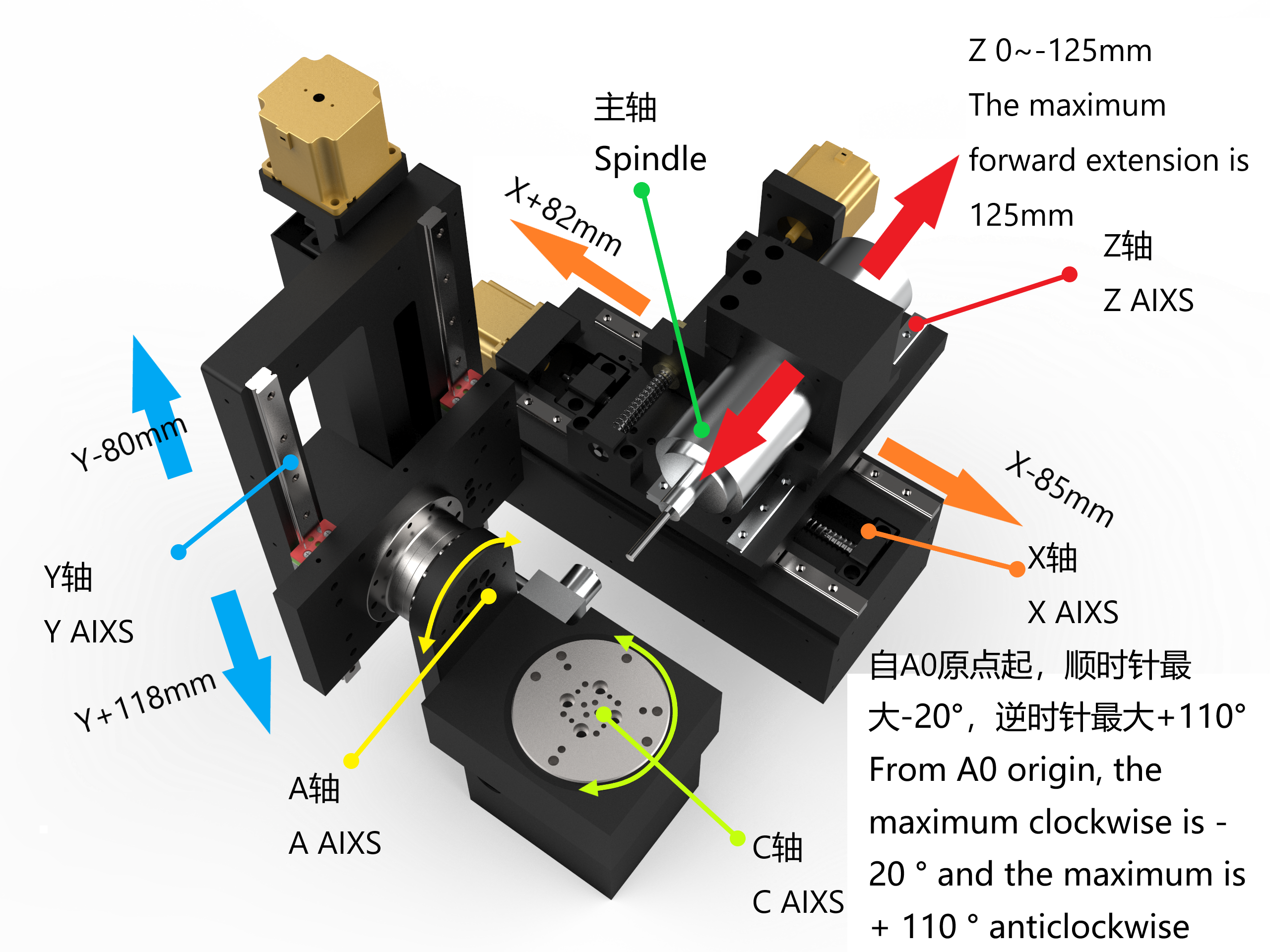

43 multi axis lathe diagram

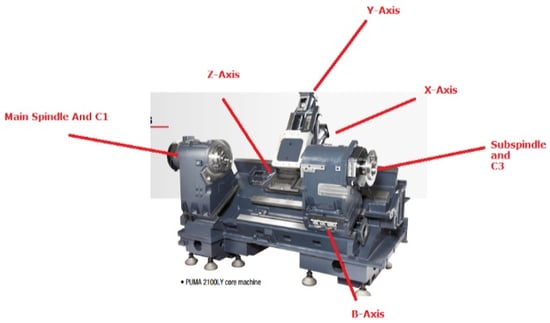

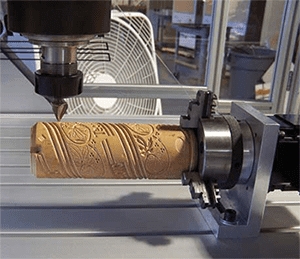

B545/735/835 Single Turret Series . High-speed 1¾" and optional 2" universal turn/mill centers with 20 HP spindle, Fanuc 31iT, 12-station turret, barfeed interface, C-axis, rigid tapping and depending on model, programmable sub-spindle, 5-hp live tooling, Y-axis. the lathe, tool vibration gave me numb hands, and tension in my neck and shoulders reminded me of the events for days after. Persistence and a bit of stubbornness won out. Now, I look forward to the challenge and adventure of creating these multi-axis rain drops and flames. Each one is a unique sculp-tural piece.

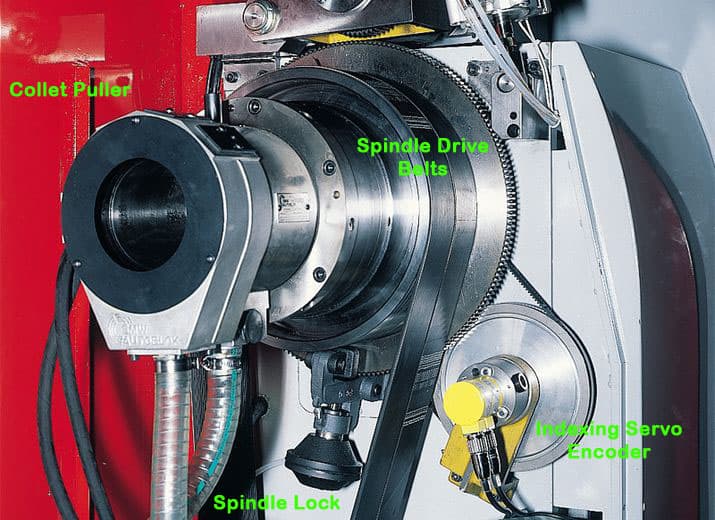

These lathes are true all-rounders and the backbone of many production operations: CNC-controlled universal turning machines by DMG MORI. The highest-possible cutting performance is ensured by spindle drives of up to 12,080 Nm. A large turning diameter of up to 930 mm, optimum chip fall, and measuring systems by MAGNESCALE for extremely precise results also ensure that these turning machines ...

Multi axis lathe diagram

Position readers are available in two versions - for use with a lathe (L version) and a milling/grinding machine (M version). They can be used with almost every conventional machine tool, perfectly saving time and improving detail processing precision. They have multiple process-enhancing functions e.g. they can automatically compute the ... 3-axis milling evolved from the practice of rotary filing, and is a milling process that operated on two axes, the X & Y axis. In three axis machining, the workpiece remains still while the cutting tool moves along the 3 axes to mill the part. 3-axis machining still one of the most widely used techniques to create mechanical parts, and can be ... 15 Apr 2001 — AccuRounds is adding multi-axis lathes, such as this Nakamura-Tome two-spindle, two-turret lathe with live tooling, to machine complex parts ...

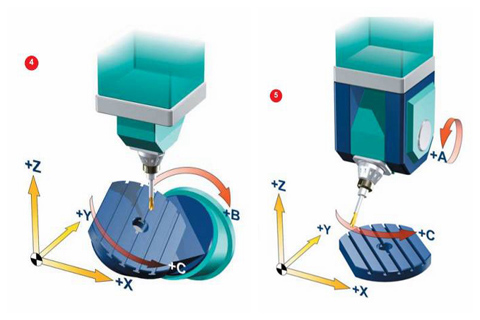

Multi axis lathe diagram. On a 5-axis machining center, the cutting tool moves across the X, Y and Z linear axes as well as ... 5-AXIS AND MULTI-TASKING MACHINE TOOL SELECTION GUIDE ... 10 Nov 2020 — The more complex the motion of the two parts, the more complex the geometry of the final machined part can be. 3-Axis machining. The most simple ... Multiaxis machining is a manufacturing process that involves tools that move in 4 or more directions and are used to manufacture parts out of metal or other materials by milling away excess material, by water jet cutting or by laser cutting.This type of machining was originally performed mechanically on large complex machines. These machines operated on 4, 5, 6, and even 12 axes which were ... Compared to CNC milling machines, CNC lathe turning machines produce parts faster and offer cheaper per-unit costs, which is advantageous for high-volume ...

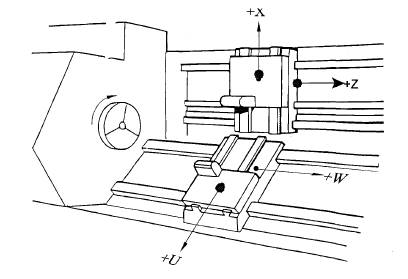

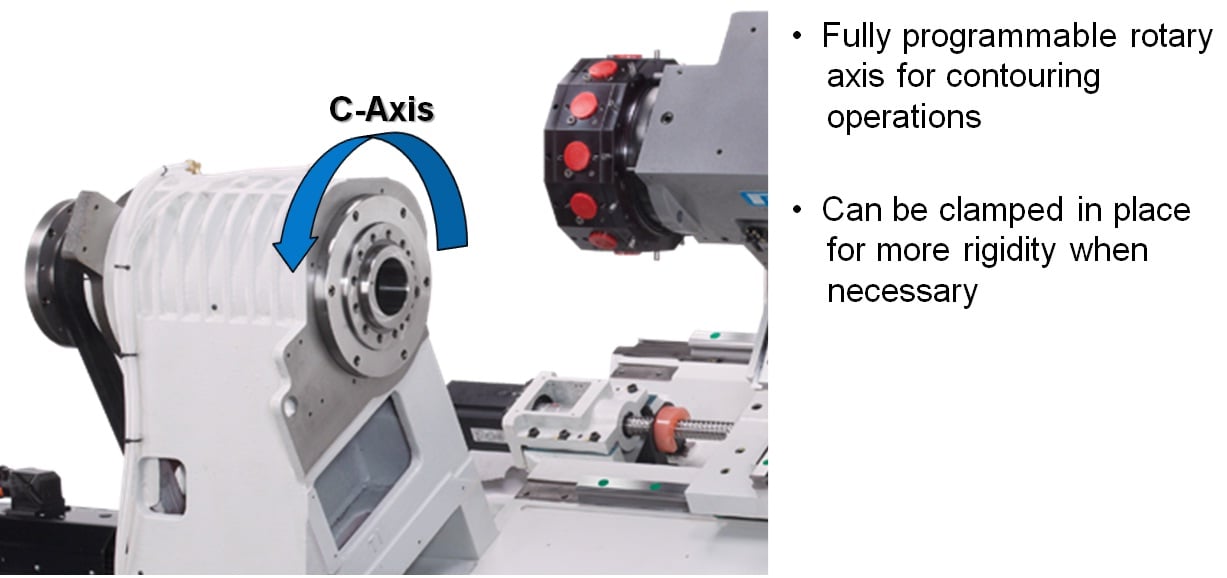

Our revolver production turning machines have up to three revolvers with three Y-axes and a built-in B-axis. Thanks to up to three tool carriers, our horizontal lathes are perfect for the series production of both bars and feed components. In addition, the versions are available with three revolvers without a B-axis and with two revolvers. by M Petruš · 2019 · Cited by 2 — Keywords: CNC program simulation; two-spindle; multi-axis CNC lathe ... To help with the programming of lathes or milling machines, Manual Guide i also ... 2-Axis CNC Lathe In this basic set-up, the 2 linear axes can be used to perform OD/ ID (i.e. cylindrical machining) and facing operations, or drilling and tapping at the centre of the part. However, it doesn't permit milling to be done. 3-Axis CNC Lathe In addition to the basic X and Z axis, C axis and life tool system are added. travel on a lathe. To carry the number line idea a little further, imagine such a line placed along each axis of the machine. Haas Lathe X and Z axis lines The first number line is easy to conceive as belonging to the left-to-right, or "Z", axis of the machine. If we place a similar number line along the front-to-back, or "X" axis, the in-

Lathes; Lathes. Okuma's broad range of vertical, horizontal, and multitasking lathes offer a variety of bore sizes, bed lengths and optional features. This variety allows us to create custom lathe solutions capable of meeting any production need. In fact, many parts can be completed on a single machine. For the machining of simple to highly complex parts, in small to large lot sizes, INDEX consistently offers economically and technologically superior solutions. Linear Guides. Linear Scales. Servo Motor. Built-In Rotary. 1-Degree Rotary. 5-Degree Rotary. Full 4th Degree Rotary. Casting. Chip Removal. Haas done-in-one Y-axis lathes allow you to perform secondary milling operations on your lathe, so you get finished parts off the machine in a single setup.

Turning a Multi-Axis Vase Craig Timmerman – craig@armadillowoodworks.com – www.armadillowoodworks.com Introduction • Turning a multi-axis vase o Inspired by Virginia woodturner, Tom Crabb o The techniques used in making this style are the basis of the other multi-axis vessels/vases I turn o Because of how the axis are set for this piece, I think it is the best multi-axis style to try for ...

According to the structure, specification, and accuracy of the multi-axis components, selecting a turning center will result in a certain functional waste, so the economical CNC lathe is chosen, so the SSCK20/500 CNC lathe is selected. 2.4.2 Machine Tool Accuracy

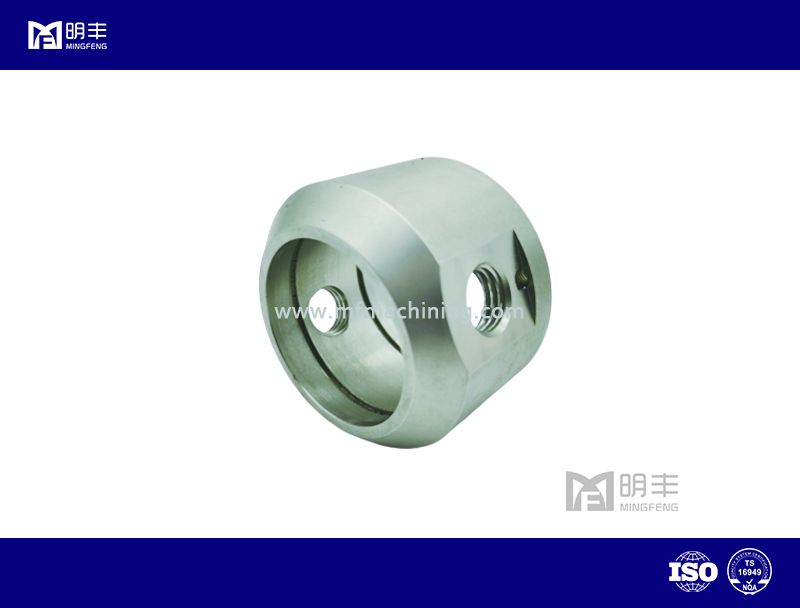

Custom 4 Axis Cnc Milling Parts Brass Machining 5 Axis Cnc Lathe Parts Aluminum Precision Cnc Machining Parts Cnc 5 Axis

The tool is inserted radially. Feed for forming: Radial. Diagram for lathe machine operation which involves facing, forming, and contour turning. 2. Facing. During machining, the workpieces are slightly longer than the finished part should be. Facing is the machining of the end of a workpiece that is perpendicular to the axis of rotation.

L Series - Multi Axis Lathe CNC Turning Centre. Home; New CNC Machines; Pinnacle; CNC Turning Centres; L Series - Multi Axis Lathe; ... TORQUE DIAGRAM. Specifications - - - - Accessories. 5 Axis CNC Machining Centres. AX Series Trunnion. AX170 Ø170mm Table; AX320 Ø320mm Table; AX450 Ø450mm Table ...

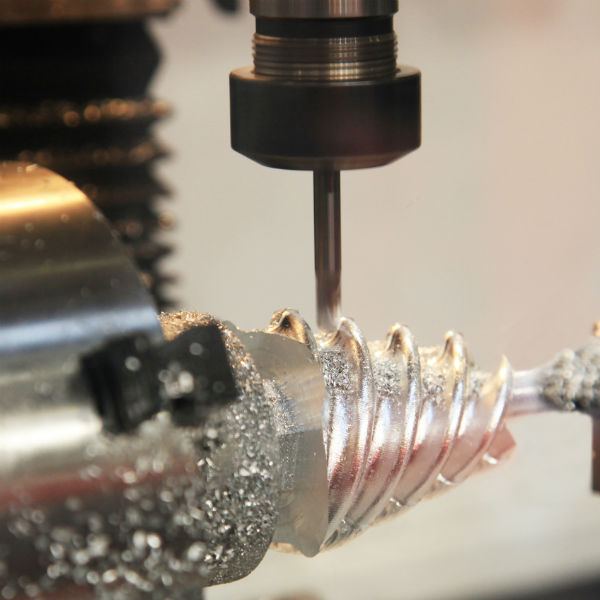

The workpiece is held on the chuck and it is made to rotate about the axis, and the tool is fed parallel to the lathe axis. The straight turning produces a cylindrical surface by removing excess metal from the workpiece. 2. Rough Turning: It is the process of removal of excess material from the workpiece in minimum time by applying high rate feed and heavy depth of cut. in rough turning the ...

Answer (1 of 4): In CNC lathe machine, the parallel direction of the spindle is Z axis. The head direction is negative (-Z), and the direction perpendicular to Z axis is X and Y directions. You can use the thumb of the left hand (X axis), the index finger (Y axis), and the middle finger (Z axis)...

The reference to axes is used to describe CNC machines which operate along multiple axis points. CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth).

China Oem Metal Precision Machining Parts Machining 5 Axis Cnc Lathe Parts On Global Sources Turning Parts Precision 5 Axis

Haas Y-axis lathes combine ±2" of Y-axis travel, full C-axis motion, and high-performance live tooling to create versatile done-in-one machining solutions for any shop. Easily perform secondary milling operations on your lathe – such as off-center milling, drilling, and tapping – to boost throughput and increase accuracy.

Fastest Precision CNC Machining Process, Metal 5-Axis CNC Lathe Milling, CNC Turning Machine Cutting#CNCMachiningPlease support me if you find my video inter...

vertical lathe. how to define an axis. 6. identification of the motion motions of nc m/t in x,y and z directions have been standardized and are followed by manufacturers. it is the relative motion of the cutting tool w.r.t. the w/p that determines + or – sign. both the m/t operators & the job planners always consider . tool to be moving about the w/p, even if the w/p acyually moves and the ...

axis. the diagram can help with visualizing placement of the new axes in relation to the center axis and to each other. Figure 3. this axis is placed at an extreme angle to the center axis, one of thousands of ways to place a new axis. 1 2 2 3 3 1. 24 American Woodturner December 2011 multiaxis spindles are accomplished by changing the profile on multiple axes. There are only two ways these ...

Position readers for lathes and milling machines ensure processing precision, measuring of angles, all-length mapping and more. Thanks to cutting-edge technology and design, ARBAH multi-axis position readout system is compatible with the majority of conventional machine tools, optical rulers and magnetic tapes. Top quality components used to manufacture our products guarantee dependability ...

The next step up from a 2-axis lathe would be a 3-axis lathe. Rather than add the Y-axis, a 3-axis lathe typically has X, Z, and C axes. C is a rotary axis parallel to the spindle axis and Z. In essence, it allows you to clock the spindle to specific angles. A three axis lathe with live toolign can do fairly arbitrary milling jobs on the part in the lathe chuck. We won’t spend any more time ...

6-axis multi-axis moving lathe, 1 axis is used for loading and unloading, and the remaining 5 axes are used for processing. Shimada Iron Works’s 6-axis lathe can be equipped with 2-station CNC guide rails, and the 8-axis automatic lathe can be equipped with 1-station CNC guide rails. Finish machining at the CNC guide rail station, rough machining at other stations. High efficiency and high ...

Multi-axis CNC Horizontal Lathe HARDINge EXPECT MORE . Hardinge designs and builds a complete range of CNC Horizontal Lathes CS MSY Series GS MSY Series Multi-Tasking CNC Turning Centers. Unique features make the GS MSY Series the best in the industry ! ... Spindle Output I Torque Diagram 22 kW motor on main spindle 15 kW motor on sub spindle

The axis parallel to the spindle axis is always Z, whether its a mill or lathe. And, for the lathe, the axis that controls the diameter is always X. C is the most common on a Lathe, as it relatively easy to turn the chuck into a C axis. Yes, Z and X are what I've heard the most of in the manual world.

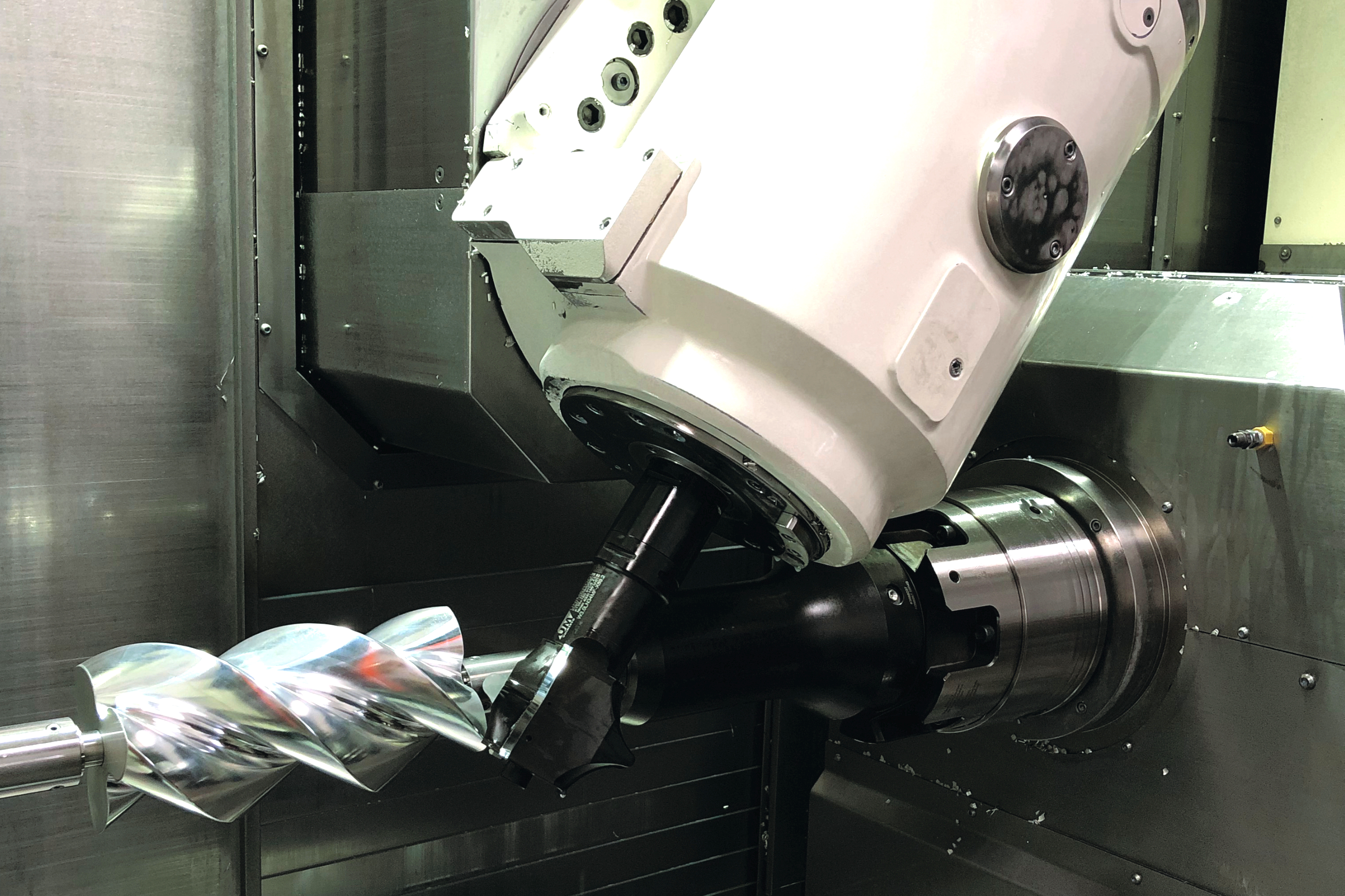

Yet there's more than one way to skin the 5-axis cat: Multitask lathes are able to mill, drill, turn, hob and more, often completing parts ...

C AXIS SERIES Standard CNC Lathe + Milling Function LA-200M Interference Diagram LA-250M Interference Diagram ø630 240 X-AXIS STR ø32 ,3630 285 X-AXIS STROKE ø32 X/ Z + C Axis - Max. Turing Dia.: ø260 mm. - Max. Turning Length: 431.5 mm. Bar Capacity: Ø52 mm. - X, Z Axis Travel: 180 x 530 mm. LA.200M LA-250M ISA LA-200M Working Range 170

Answer (1 of 3): 3 axis are the tool up-down, and tool or bed right-left and to-fro (front-back) 1 axis to spin the tool 1 axis to rotate the part being worked 1 axis to rotate the tool head 1 axis to remove the part and reclamp to work the back .. 7- Axis Contour Milling of a 6 sided ...

The derived model consist of the controller, axis drive and the spindle drive of a CNC turning machine and their connection through the cutting process. The overall model uses a modular multi-model approach to prototype the machine tool and its process. Keywords: Block-diagram, Lathes, modelling, simulation, dynamic 1 Introduction

3 Mar 2021 — 9-Axis CNC Machining. The 9-axis CNC blends lathe and 5-axis machining. As a result, the part can be turned and milled along various planes in ...

15 Apr 2001 — AccuRounds is adding multi-axis lathes, such as this Nakamura-Tome two-spindle, two-turret lathe with live tooling, to machine complex parts ...

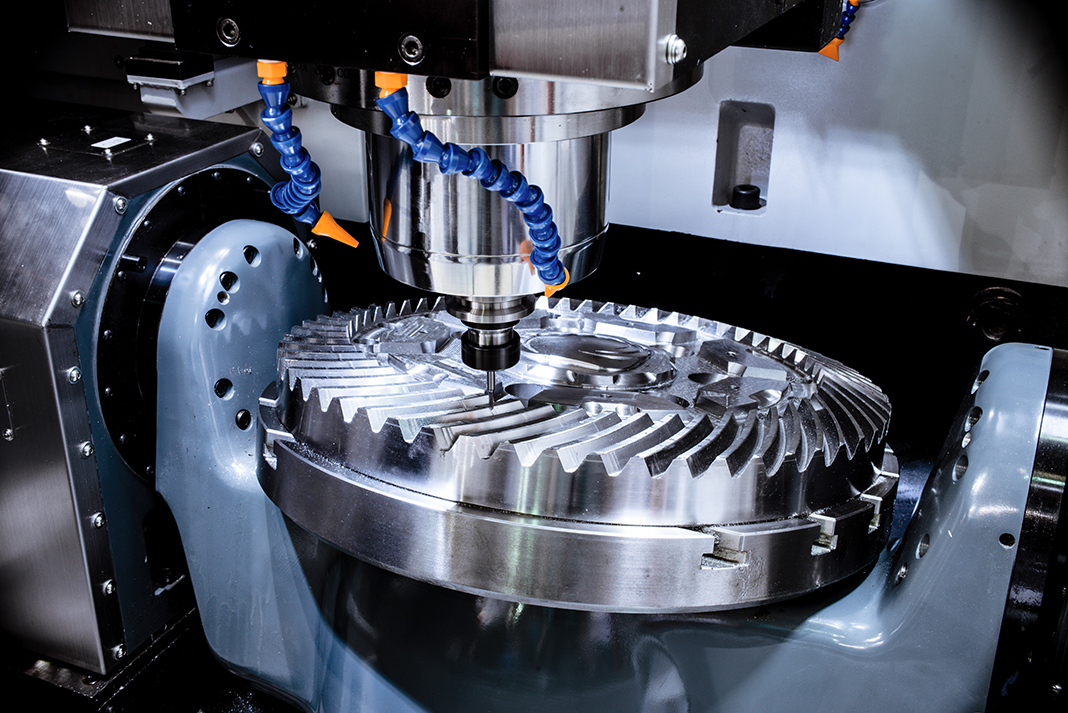

3-axis milling evolved from the practice of rotary filing, and is a milling process that operated on two axes, the X & Y axis. In three axis machining, the workpiece remains still while the cutting tool moves along the 3 axes to mill the part. 3-axis machining still one of the most widely used techniques to create mechanical parts, and can be ...

Position readers are available in two versions - for use with a lathe (L version) and a milling/grinding machine (M version). They can be used with almost every conventional machine tool, perfectly saving time and improving detail processing precision. They have multiple process-enhancing functions e.g. they can automatically compute the ...

China Custom 4 Axis Cnc Milling Parts Brass Machining 5 Axis Cnc Lathe Parts Aluminum Cnc Machined Parts On Global Sources Cnc Milling Parts Brass Machining 5 Axis Cn Cnc Machined Parts

Comments

Post a Comment